Air Leakage

Air leakage refers to the unintentional or undesired flow of air through gaps, cracks, or openings in a building’s envelope or ductwork system. It can occur in residential, commercial, or industrial buildings and can have several negative effects, including energy loss, decreased comfort, and increased utility bills.

In residential buildings, common areas of air leakage include windows, doors, attic hatches, electrical outlets, and gaps around pipes, wires, and vents. In commercial or industrial buildings, air leakage can occur through gaps in walls, roofs, windows, and poorly sealed joints in the HVAC (heating, ventilation, and air conditioning) system.

Here are a few reasons why air leakage is a concern:

- Energy Loss: Air leakage allows conditioned air (heated or cooled) to escape the building while letting outside air infiltrate. This leads to energy waste as your heating or cooling systems have to work harder to maintain a comfortable indoor temperature.

- Decreased Comfort: Air leakage can cause drafts, cold spots, or hot spots, making it difficult to maintain consistent temperatures throughout the building. It can also allow dust, pollutants, and outdoor noise to enter the interior space.

- Increased Utility Bills: When air leaks out, it requires more energy to maintain the desired temperature. As a result, your heating and cooling systems have to work longer and consume more energy, leading to higher utility bills.

- Indoor Air Quality Issues: Uncontrolled air leakage can bring in pollutants, allergens, and outdoor contaminants into the building, impacting indoor air quality. This can be a concern for individuals with respiratory issues or allergies.

To address air leakage, you can take several steps:

- Identify Air Leaks: Perform a thorough inspection of your building to identify areas of air leakage. Look for visible gaps, cracks, or openings in the building envelope, windows, doors, and the HVAC system.

- Seal Gaps and Cracks: Use caulk or weatherstripping to seal gaps around windows, doors, and other areas where air may be leaking in or out. Apply weatherstripping to the sides and bottom of doors, and use caulk to seal gaps around windows and other openings.

- Insulate: Proper insulation helps reduce heat transfer through the building envelope, minimizing air leakage and improving energy efficiency. Insulate walls, attics, and crawl spaces using appropriate insulation materials.

- Air Duct Sealing: In HVAC systems, ductwork can develop leaks over time. Have a professional inspect and seal any leaks in the ducts to prevent air leakage and improve system efficiency.

- Window and Door Upgrades: Consider upgrading old, inefficient windows and doors with energy-efficient models that have proper seals and insulation.

- Air Leakage Testing: In some cases, it may be beneficial to conduct a blower door test or thermal imaging to assess the extent of air leakage and identify specific problem areas.

Addressing air leakage not only helps improve energy efficiency and comfort but also contributes to a healthier indoor environment. Consider consulting with a professional energy advisor to assess your building’s specific needs and recommend appropriate measures for mitigating air leakage.

1. Control of Airflow in Buildings

Controlling airflow in low‐rise and high‐rise buildings is important for maintaining indoor air quality, ensuring occupant comfort, and optimizing energy efficiency. Control of airflow in a building depends on both the pressure difference across the building enclosure and the permeability of the separator. Here is a breakdown of how both factors play a role:

- Pressure Difference: Mechanical systems, such as HVAC systems, are responsible for controlling the pressure difference within a building. Positive pressure can be created by supplying more air into a space than is exhausted, while negative pressure can be created by exhausting more air than is supplied. By manipulating the pressure difference, mechanical systems can influence the direction and rate of airflow within the building. This is particularly important for controlling ventilation, maintaining indoor air quality, and preventing the migration of pollutants or odors between spaces.

- Permeability of the Separator: The building enclosure air barrier and interior compartmentalization control the permeability of the separator, which refers to the resistance to airflow. This is achieved through the use of air barriers, such as the materials and systems mentioned earlier, which limit the passage of air through the building envelope. A properly designed and installed air barrier system can significantly reduce unwanted airflow, preventing air leakage and maintaining the integrity of the building enclosure. Interior compartmentalization, such as walls, floors, and partitions, also contributes to controlling the airflow by acting as physical barriers.

By combining the control of pressure difference through mechanical systems and the control of permeability through building enclosure air barriers and interior compartmentalization, it is possible to regulate and manage airflow within a building. This approach ensures that ventilation and air distribution are properly controlled while minimizing energy losses due to air leakage.

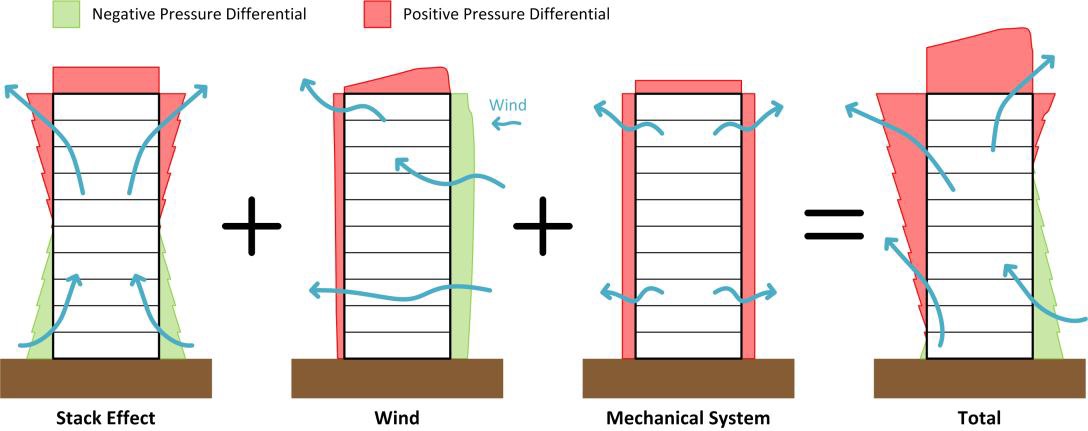

Fig.1. Cumulative effect of driving forces of air movement on a tall building

1.1. Pressure Difference

Mechanical systems play a significant role in controlling airflows within buildings and can be used to intentionally manipulate pressure differences for various purposes. For example, corridor pressurization ventilation systems are designed to raise the pressure in the interior common corridor of a building to help control the movement of smoke and odors within the building by creating a positive pressure zone in the corridor that prevents their spread into the dwelling units. They also provide ventilation to individual units as fresh air is drawn in from the corridor. The same approach can be taken in laboratories that handle hazardous or dangerous contaminants. In these situations, the laboratory room is often depressurized relative to surrounding spaces using mechanical ventilation. This negative pressure differential ensures that any potential contaminants are contained within the lab, minimizing the risk of their transfer to other areas.

These applications demonstrate how mechanical systems can be used to intentionally control airflows and pressure differentials for specific purposes, such as providing ventilation, managing smoke or odors, or maintaining containment of hazardous substances.

1.2. Permeability of the Separator

The building enclosure air barrier and interior compartmentalization control the permeability of the separator, which refers to the resistance to airflow.

1.2.1 Exterior Enclosure Air Barrier Systems

There are several common air barrier strategies for walls for achieving airtightness targets:

Sealed Polyethylene Approach

The Sealed Polyethylene Approach is a method for creating an airtight barrier using polyethylene sheeting. It offers simplicity and ease of installation, making it suitable for a range of construction projects. However, it is important to note that the success of the Sealed Polyethylene Approach depends on proper installation techniques and attention to detail. The polyethylene sheeting must be carefully installed and sealed to ensure a continuous and durable air barrier.

Airtight Drywall Approach (ADA)

The Airtight Drywall Approach (ADA) is a method for creating an airtight barrier using a combination of gaskets, sealants, and careful installation techniques during drywall installation. The Airtight Drywall Approach offers several advantages, such as simplicity of installation, compatibility with standard construction practices, and minimal disruption to interior finishes. It can be particularly effective in retrofit situations or areas where other exterior air barrier approaches may not be feasible.

Exterior Approaches

A significant advantage of exterior approaches is that penetrations of the interior wall finish for electrical outlets and disruptions such as stairs, plumbing fixtures, and partitions, do not affect the continuity of the air barrier. The Sealed Sheathing Approach, along with variations that incorporate additional sealant joints or membrane strips, provides an effective exterior air barrier strategy that helps maintain continuity and minimize disruptions from interior penetrations. Proper installation techniques, attention to detail, and adherence to industry best practices are essential to ensure the desired level of airtightness and maximize the energy efficiency and comfort of the building.

Exterior approaches are divided into two primary categories depending on whether the exterior sheathing (i.e. gypsum, plywood, oriented strand board (OSB) etc.) is sealed or whether the water resistive barrier (WRB) outside of the sheathing is sealed (i.e. self‐adhered membranes (SAM), spun bonded polyolefin (SBPO), self‐adhered vapour permeable membrane, liquid membrane, etc.):

- Sealed Sheathing Approach

- Sealed Sheathing Membrane Approach

- Unsupported Sheet Membranes

- Supported Sheet Membranes with vertical strapping

- Sandwiched Membranes behind exterior insulation

- Self‐Adhered and Liquid Membranes

Spray foam

Closed-cell polyurethane spray foam is a popular option for creating a primary air barrier on the exterior of sheathing in building construction. It offers the advantages of both air sealing and thermal insulation. Spray foam is able to fill voids, holes, and transition interfaces well, but it can’t address details and small cracks, gaps, and transitions requiring additional materials (sealants, tapes etc.). While spray foam insulation has numerous benefits, it also has some limitations to consider. Over time, spray foam insulation may experience slight shrinkage or off-gassing, which could affect its long-term performance. Properly monitoring and addressing any issues that arise are necessary to maintain the integrity and effectiveness of the insulation.

- Monolithic Material (Cast‐in‐place Concrete)

This type of air barrier can serve as an effective air barrier if designed and constructed properly. The primary concerns with the system are with regard to proper concrete consolidation, cracking, and continuity of airtightness across the concrete joints. It is worth noting that while cast-in-place concrete can serve as an air barrier, it may still require additional air sealing measures, such as the use of compatible sealants or tapes at specific joints or penetrations. Proper design, construction techniques, and attention to detail are crucial to ensure the effectiveness of cast-in-place concrete as an air barrier.

Note: Concrete block walls are commonly used in building construction, including as exterior infill walls. Due to the inherent porosity of the blocks and mortar joints, additional air barrier measures are necessary to ensure effective air sealing.

- Window Wall and Curtain Wall

The air barrier system within window wall and curtain wall systems consists of the glass, frames, gaskets, and sealants that connect and join components together and at interfaces to other assemblies.

- Other Approaches

An additional air barrier approach used in wood‐frame construction in Europe and commonly in Passive House construction is the use of thick insulated wood‐frame walls with taped and sealed plywood or OSB sheathing at the interior surface as the air barrier. Special pressure adhesive tapes are used to tape the joints in the plywood and between elements to create a continuous air barrier when properly applied. the rigidity and visibility of this approach generally results in very airtight buildings and is a potential solution for mass‐timber and other prefabricated walls.

1.2.2. Compartmentalization

Air barrier systems can be utilized as a part of internal building separations to control airflow within a building. While they have traditionally been implemented for fire and smoke control and acoustic purposes, they also offer an effective means of managing in-service airflows. By incorporating air barrier systems within internal building separations, spaces within the building can be compartmentalized, allowing for more predictable and controllable airflow patterns. By implementing air barrier systems as part of internal building separations, the movement of air between different spaces can be more effectively controlled, ensuring desired airflow patterns, temperature zones, ventilation rates, and noise levels.

This can be done by creating an airtight perimeter between the dwelling unit, the common corridor (if present), and the adjacent dwelling units (to the sides, above and below). In practice, this is not a difficult task because a separation is intended between dwelling units, as well as between dwelling units and corridors or other public spaces. The two primary focal points are sealing wall and ceiling penetrations, and creating a relatively airtight entry door (this assumes that the ventilation strategy does not utilize the door undercut approach) as well as sealing the doors and openings of vertical shafts including the elevator and stairwells. Proper detailing for fire, smoke and sound control will tend to be airtight.

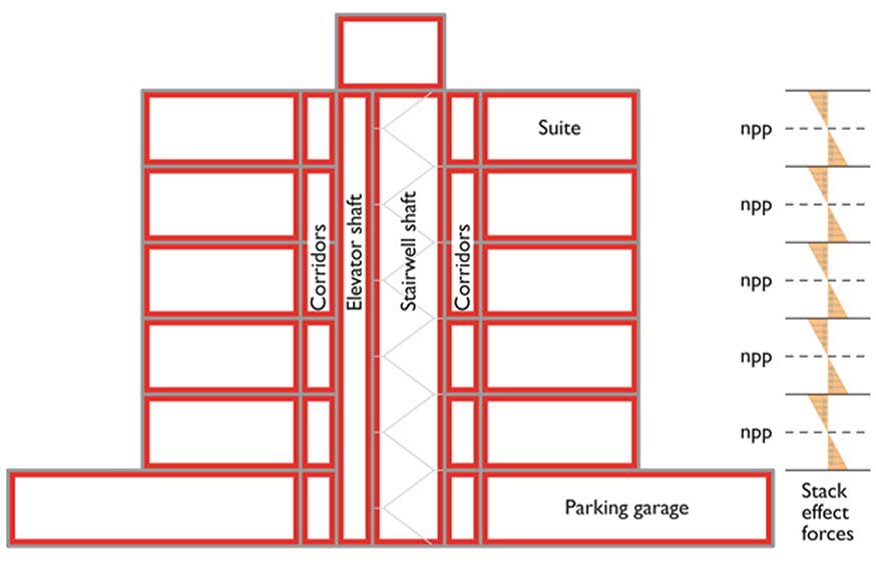

Compartmentalizing the interior spaces of a building has an impact on stack effect forces. Stack effect refers to the natural movement of air driven by temperature differences and the resulting pressure variations in a building. It occurs due to the difference in indoor and outdoor air densities, creating a pressure imbalance. When a building is compartmentalized, the stack effect forces are confined to each individual floor or compartment rather than acting over the entire height of the building. This occurs because the physical barriers created by compartmentalization restrict the vertical airflow between floors or compartments. The compartmentalization of interior spaces helps to mitigate the stack effect by limiting the vertical movement of air and reducing the pressure differentials between different levels of the building. It is important to note that while compartmentalization can help mitigate stack effect forces, it does not eliminate them entirely. Other factors such as building height, building orientation, outdoor weather conditions, and the presence of mechanical ventilation systems also influence the magnitude of the stack effect.

Fig.2. Compartmentalization of the interior spaces of a building and impact on Stack Effect Forces

2. Airtightness Testing

Airtightness testing is a valuable tool for assessing the performance of air barrier assemblies in buildings. It provides quantitative and qualitative information about the effectiveness of the air barrier system, and it can be used in various stages of the building lifecycle. By combining quantitative airtightness testing with qualitative methods, a comprehensive assessment of the air barrier performance can be achieved. It enables comparisons with specified targets, standards, and industry averages, providing a basis for evaluating the effectiveness of the air barrier assembly and identifying areas for improvement.

It is worth noting that airtightness testing should be conducted by qualified professionals using appropriate equipment and following recognized standards and protocols, such as ASTM E779, CGSB 149.10, ISO 9972, or other available quantitative testing standards. This ensures accurate and reliable results, allowing for informed decision-making regarding the building’s airtightness and energy performance.

2.1. Blower Door System

Blower Door Systems, also known as Fan-Door Systems, are widely used in building performance testing to assess the airtightness of buildings. These systems consist of a calibrated fan and a frame (door) that is temporarily installed in an exterior opening of the building, typically a doorway. The fan creates a pressure difference between the inside and outside of the building, and measurements are taken to determine the airflow through leaks in the building envelope.

The data collected from the blower door system, including pressure readings and airflow measurements, is used to calculate the building’s air leakage rate. This information helps assess the building’s airtightness, locate specific areas of air leakage, and guide air sealing efforts to improve energy efficiency and occupant comfort.

Blower door testing is commonly performed during construction, energy audits, or retrofits to evaluate the effectiveness of air sealing measures, verify compliance with energy codes or standards, and identify areas that require improvement.

Overall, the blower door system is a valuable tool for assessing a building’s airtightness, quantifying air leakage rates, and guiding air sealing strategies. It provides objective data that supports energy efficiency improvements and helps create more comfortable and sustainable buildings.

3. Diagnostic Testing

3.1 . Smoke Testing

Smoke generators are indeed a valuable tool for qualitative air leakage testing. They are commonly used to visualize air movement and identify potential air leakage pathways in buildings. By generating a controlled amount of smoke, these devices can help detect and track the flow of air through cracks, gaps, or other openings in the building envelope.

Qualitative air leakage testing using smoke generators is particularly useful when trying to locate air leakage pathways that may not be easily visible or accessible. It allows for a visual demonstration of airflows and helps pinpoint specific areas for further inspection or sealing.

3.2. IR Thermography

IR Thermography, also known as Infrared Thermography or Thermal Imaging is a technique that uses Infrared Cameras to capture and analyze the infrared radiation emitted by objects and surfaces. It allows for the visualization and measurement of temperature variations, providing valuable insights into the thermal performance of buildings and identifying potential issues.

Infrared cameras are particularly useful in identifying air leakage because they can detect temperature anomalies on the surface of building components. When there is air leakage, the temperature of the affected area can be different from the surrounding surfaces due to the exchange of air with different temperatures. These temperature anomalies can be captured and visualized using an infrared camera.

By conducting an infrared inspection, areas of air leakage can be identified as they typically exhibit temperature variations. For example, during a blower-door test, where the building is pressurized or depressurized, the infrared camera can help locate air leakage points by detecting colder or warmer spots on the surface of walls, windows, doors, or other building components. These temperature anomalies indicate the presence of air movement and potential areas of energy loss or moisture intrusion.

The ability to visualize relative surface temperatures using an infrared camera allows for efficient identification of air leakage pathways, even when they may not be visually apparent. This information is valuable in prioritizing and addressing air sealing measures to improve the airtightness and energy efficiency of the building.